Last Year's Favorite False Dilemma

Welcome to the 72nd edition of The LogTech Letter, and the first of 2022. TLL is a weekly look at the impact technology is having on the world of global and domestic logistics. Last week, I explored the growth of founders themselves investing back into the LogTech arena. This week, I’m pondering why supply chain practitioners are expected to choose between resiliency and efficiency.

As a reminder, this is the place to turn on Fridays for quick reflection on a dynamic, software category, or specific company that’s on my mind. You’ll also find a collection of links to stories, videos and podcasts from me, my colleagues at the Journal of Commerce, and other analysis I find interesting.

For those that don’t know me, I’m Eric Johnson, senior technology editor at the Journal of Commerce and JOC.com. I can be reached at eric.johnson@ihsmarkit.com or on Twitter at @LogTechEric.

If there was one consultant-esque theme that kept recurring in ‘21, it was this: supply chains need to move from just-in-time to just-in-case. It doesn’t take a genius to figure out why this became the mantra last year. Intense disruption rippling across global and domestic supply chains put into sharp focus the areas where “lean” turned into “desperate.”

The idea that efficiency is out, and resiliency is in, became so pervasive, it feels almost like gospel now, at least among the advisory and policy class of those who opine how supply chains will or should transform. See this incorrect equation in full view below:

To which I say, hogwash. No matter how dramatic the environment became in ‘21, no matter how high freight rates rose, no matter how long transit times extended, a decades-long trend doesn’t reverse itself in one year. And I’d argue, nor should it. Why should resiliency replace efficiency? Why should just-in-case replace just-in-time? Why would they be considered opposites?

Let’s stipulate that the pandemic did expose the frailties of a perfectly lean supply chain, one set up to withstand the normal bumps and bruises, but not a 100-year-shock. But what was exposed was not that supremely efficient supply chains were totally wrong, just that only utilizing one type of supply chain strategy across the board was risky. In other words, the lesson to be learned from 2021 was not that just-in-time was wrong, it’s that just-in-time isn’t always right. Flipping from one extreme to the other, to highly resilient supply chains with extra buffer stocks and back-up suppliers and sourcing regions isn’t the answer because that’s also an all-or-nothing scenario.

We should view purely just-in-time and purely just-in-case supply chains as pretty close in nature rather than polar opposites. That is to say they are both extreme positions to take.

The reality, however, is that every supply chain is somewhere between those extremes. It makes no sense to think of resiliency and efficiency as some sort of tradeoff. As the famous meme tells us…

Supply chain managers have to account for resiliency and efficiency. They can’t choose between the two, and nor should they. Efficiency shouldn’t be sacrificed at the altar of building the church for Easter. Resiliency shouldn’t sacrificed at the altar of zero excess inventory. Only a zealot would choose one path or the other.

I think of this like I do the seemingly never-ending quandary about keeping schools open or closed during Covid. The idea that schools should remain open or closed NO MATTER WHAT is nonsense. Covid, and all its trying and peculiar waves, is not a static challenge. The dynamics - both the state of the virus itself, our vaccinations and remedies, and the grander knowledge of how to mitigate it and treat it, change in real time. If your position is that something must always happen no matter how the internal and external dynamics change, you’re setting yourself up to fail, and for disappointment.

Here’s where technology comes in. Systems that allow supply chain managers to toggle between options that account for resiliency and efficiency are what changes the picture. The ability to weigh, say, carrying excess inventory against the likelihood that your goods, or components that go into your product, are likely to run out soon. The ability to push demand signals upstream to stay lean. The ability to incorporate risk data into procurement or routing choices. None of this is easy, but it is all on the market, waiting to be assembled. Because the choice isn’t real just-in-time or just-in-case, it’s all of the above.

Here’s a roundup of recent pieces on JOC.com from my colleagues and myself (note: there is a paywall):

The buy versus build dilemma is one as old as time - or at least as old as the computer. I explored how this dilemma is also not an either/or situation through the lens of Kingsgate Logistics, which in Q4 turned to Trucker Tools for a carrier portal to complement its in-house-developed TMS.

Blume Global is intent on breaking out of the visibility box, and its acquisition this week of manufacturing supplier collaboration portal Live Source puts it on a path with multifaceted platforms like E2open.

For our 2022 Annual Review and Outlook edition, I wrote about how a bumper year shouldn’t delude forwarders into failing to see the challenge ahead, from startups, from commerce platforms, and from container lines.

And here are some recent discussions, reports, and analysis I found interesting:

Had an awesome time chatting with Kyle Henderson at Vizion on his Full of Ship podcast about tech, port congestion, and mainstream media’s fascination with logistics.

If you missed the latest episode of LogTech Live earlier today, you missed my fantastic discussion with Tobenna Arodiogbu, CEO of CloudTrucks, a seasonal dadjoke, my take on decentralization, and more. Here’s a link to the episode:

A great thought from Harry Stebbings of 20 Minute VC…

TPMTech Session in Focus:

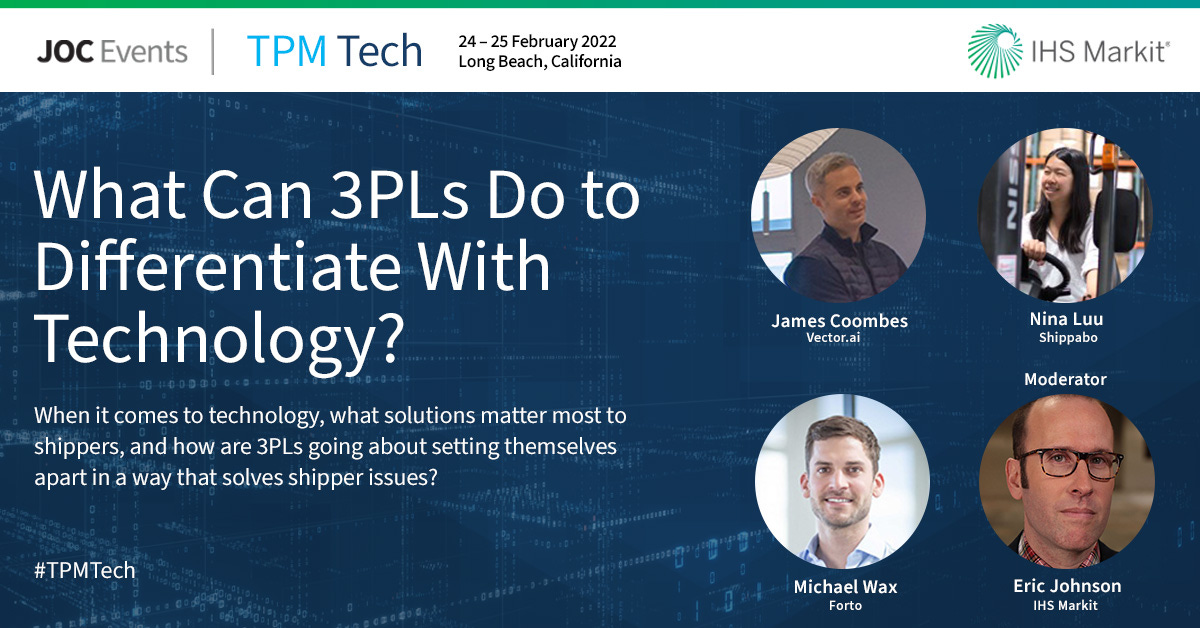

From now until TPMTech in late February, I’ll be spotlighting a different session at our upcoming event, to be held Feb 24-25 in Long Beach, Calif. You might be noticing a theme at this year’s conference: a lot of sessions around forwarding technology. Why? Because I see forwarding at the crossroads of the logistics industry and the transformation of the industry. The biggest funding rounds have gone into digital intermediaries and yet there is a huge amount coming into technologies that aid existing forwarders. At the heart of this issue is a simple question: how to differentiate in a market with literally tens of thousands of competitors of all shapes and sizes? I’ll be digging into this question with a stellar group of experts at 9:40 am PT Feb. 25.

Some upcoming events I’ll be involved in:

The third and final webcast in our Logistic Technology series is Jan. 13, where DCSA CEO Thomas Bagge, Gateway Global Logistics CEO Caitlin Murphy, and Terminal49 CEO Akshay Dodeja will join me to discuss how to drive standardization in the global logistics industry. Registration is free.

Disclaimer: This newsletter is in no way affiliated with The Journal of Commerce or IHS Markit, and any opinions are mine only.